Is it easy to DIY an e-bike battery pack?

DIY battery packs require a certain technical threshold.

Battery cell matching and capacity division are extremely important. It is necessary to select batteries with consistent voltage/internal resistance/capacity, otherwise the battery pack life will be shortened (the battery pack will be scrapped in a short period of time), and some batteries will be overcharged/over-discharged, leading to the risk of thermal runaway.

How to choose the right battery?

Commonly used battery cell types:

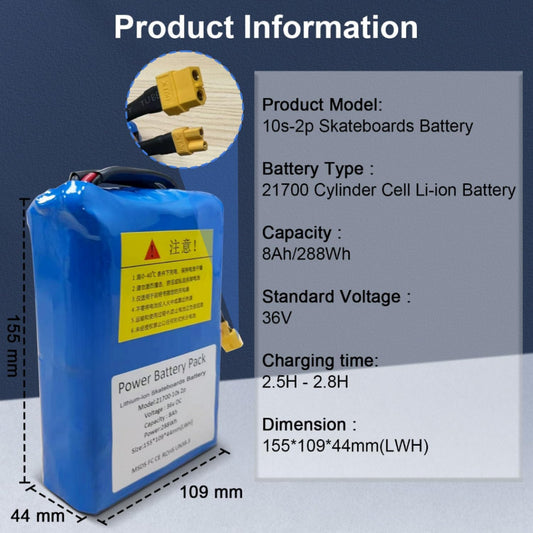

The common batteries on the market are 18650 and 21700. The battery you use should be consistent with the original battery of your electric bikes.

If your original battery is 18650 and you want to get a larger capacity battery, you can try to open the old battery box to see if there is enough space inside to accommodate a larger 21700 battery (Samsung's 21700-58T has a maximum capacity of 5600 mah).

Or you can use a 18650 battery with a larger capacity on the market (the currently known maximum capacity is 4000 mah).

Discharge capacity (C-rate):

Continuous discharge current = Motor power / Battery pack voltage

The nominal 21700 battery cell is 5Ah 3C, so the continuous discharge current of a single cell = 5Ah × 3 = 15A

For example: The operating current required by a 48V 1000W motor is: 1000W / 48V ≈ 20.8A

To ensure the normal operation of a 1000W motor, the required current is 20.8A. You need to select 21700 5Ah 3C cells and configure a battery pack with 13 series and 2 parallels. Because the battery pack is a 2P configuration (15A×2=30A), its total current of 30A is greater than the required 20.8A.

The calculation formula for the number of battery cells in parallel is:

Minimum parallel number (P) = Maximum continuous discharge current of the motor / (single cell capacity × discharge C rate)

Recommended plan:

48V 20Ah ternary lithium battery pack

· Battery: 21700 5Ah (4.2V fully charged)

· Series-parallel: 13S4P (13×4.2V=54.6V, 4×5Ah=20Ah)

· BMS: 48V 13S 30A (continuous), with balancing function

· Applicable motor: 500W~1000W (continuous current 10A~20A)

Battery brand and quality:

Ternary lithium: LG, Samsung SDI, Panasonic, EVE, FST, BAK, etc. If the budget is sufficient, it is recommended to choose traditional well-known brands such as LG and Samsung; you can also choose cost-effective Chinese brand batteries.

Consistency requirements:

Voltage difference: The voltage difference of a new battery cell should be ≤0.01V (capacity matching is required before assembly).

Internal resistance difference: The internal resistance difference of the same batch of batteries is ≤5mΩ.

Chinese first-tier brand battery cells: high cost performance (20-30% lower than Japan and South Korea), stable supply chain, suitable for the mass market.

Japanese and South Korean battery cells: leading technology, excellent consistency, suitable for high-end needs.

If you pursue extreme performance and have sufficient budget, you can choose Japanese and Korean battery cells such as LG, SAMSUNG, SONY, etc.; if you focus on practicality and cost, Chinese first-tier brands such as EVE and LS, FST are completely reliable choices.

It is recommended to purchase battery cell kits that have been strictly divided and matched.

How to choose a compatible BMS configuration?

BMS (Battery Management System) Configuration:

Wrong selection (such as insufficient continuous current) will cause the BMS to burn out or protection failure. Therefore, you should choose a battery BMS with the same technical parameters as the original one.

First, the voltage:

The BMS needs to match the rated voltage of the original battery pack (such as 36V, 48V, 60V, etc.). This parameter can be easily seen on the original battery label.

Number of strings (S):

For example, 48V lithium batteries usually have 13 strings (13S, fully charged is 54.6V), and you need to confirm the number of strings supported by the BMS.

Discharge current value:

Continuous discharge current: Select according to the motor power (for example, for a 500W motor, the 48V system current is about 10.4A, it is recommended to select a BMS of 20A or more to leave a margin).

Peak current: Short-term high load (such as climbing) requirements, it is necessary to ensure that the BMS can withstand it (such as nominal 30A, peak 60A).

Battery type compatibility: Clarify the battery chemical type (ternary lithium, lithium iron phosphate, etc.). Different batteries have different charge and discharge curves and protection voltages (for example, a single ternary lithium cell is fully charged at 4.2V, while a lithium iron phosphate cell is 3.65V).

Protection function: Overcharge, over discharge, over current, short circuit, temperature protection (need to support high temperature/low temperature cut-off).

Balance function: Passive balance (common) or active balance (more efficient, high cost), balance current (such as 50mA-200mA). If the budget is sufficient, it is recommended to purchase an active balance protection board, which can extend the life of your battery.

Brand and reliability: Give priority to well-known brands (such as Daly, JK BMS, Ant BMS) to avoid battery damage or safety hazards caused by inferior BMS.

1. What are the risks of DIY e-bike battery pack? How to DIY electric bike battery pack more safely?

At present, a large part of the electric bicycle battery packs on the market use 18650, 21700 and other lithium-ion cells. 18650 and 21700 lithium-ion cells have high energy density. If they are improperly operated (such as short circuit, overcharge, over discharge, physical damage, welding overheating, temperature runaway), they are very likely to cause thermal runaway, causing the battery pack to catch fire or even explode violently. Moreover, lithium-ion battery fires are difficult to extinguish and produce toxic gases. In addition, incorrect configurations: such as incorrect series-parallel configurations, BMS selection or connection errors, may cause abnormal battery pack performance, shortened life, and even cause safety hazards.

Therefore, when assembling battery packs, especially when welding battery packs, try to avoid misplacing the nickel sheet, tools slipping, and insulation of the positive and negative poles of the connecting wires to avoid accidental short circuits; before assembling the battery, make adequate safety preparations. For example, the orderly placement of materials and tools, designing the series and parallel connection of batteries in advance, and deeply understanding the working principle of BMS (charge and discharge protection, balancing, temperature monitoring, etc.) and selecting BMS with appropriate specifications (voltage, current, function), and understanding how to correctly connect BMS (with battery cell series, sampling lines, charge and discharge ports). Finally, choose a safe place away from flammable materials.

Before assembling the battery, you need to learn some professional knowledge: for example, knowledge of battery cells, you need to understand the specifications of battery cells, such as voltage, capacity, internal resistance, discharge rate C number, etc. At the same time, you need to do a good job of matching the battery cells (the equipment needs to match the battery cells with very close voltage and internal resistance, and the error is usually required to be less than 0.05V).

2. What materials and tools are needed to DIY ebike battery pack?

DIY battery packs require some professional tools: such as spot welders, multimeters, battery internal resistance testers (if the battery supplier has helped you with capacity matching, internal resistance testers are not needed), insulating materials, nickel sheets/copper connectors, brackets/molds, insulating gloves, etc.

In fact, you can find and buy DIY kits (such as matching battery cells, BMS, brackets, shells, etc.), which can save a lot of cost and time to buy equipment.

If you want to save the trouble of DIY battery packs and avoid the risk of fire and explosion during assembly, purchasing qualified battery packs is the best choice.